Robotics

Robotics

Industrial Robotics

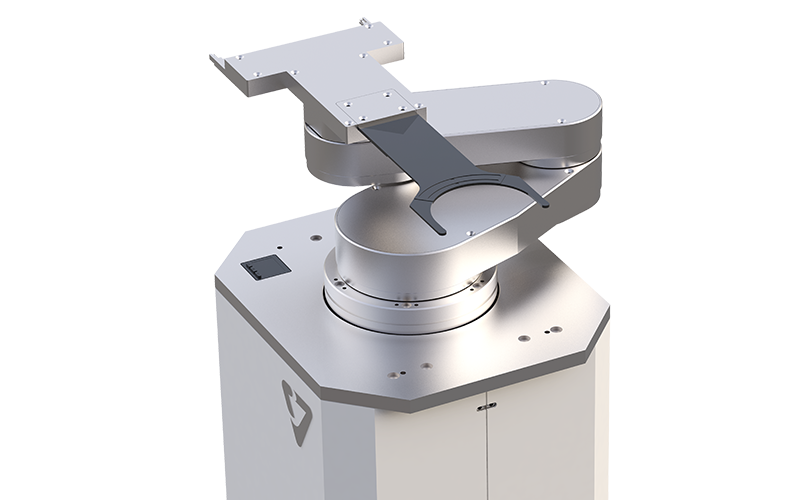

VSW-S3160

Cleanroom-Compatible VSW Series

Uses an absolute servo motor, offering high precision and reliability.

Applies various types of grippers, making it suitable for work transfer in different environments.

Features

Enables fast and safe wafer handling with precise operation and optimized motion.

Selectable base type or flange type depending on the installation environment of the equipment.

Provides high reliability and maintenance convenience.

Allows encoder battery replacement without opening the cover.

Intuitive teaching pendant UI configuration.

Robot

| Specification | Index WTR Single | Index WTR Double |

|---|---|---|

| Model | VSW-S3160-300-AV-M | VSW-D4160-300-AV-M |

| Handling Object | 8 inch Wafer (STD) | 12 inch Wafer (STD) |

| Grip Method | Vacuum grip (STD) | Vacuum grip (STD) |

| Min Rotate Dia. | Ø 450 mm | Ø 570 mm |

| Gripper Reach | 525 mm | 580 mm |

| Configuration of Axis | R / T / Z (3 Axis) | R1 / R2 / T / Z (4 Axis) |

| Coordinate System | Cylindrical | Cylindrical |

| Repeatability | Within ±0.1 mm | Within ±0.0.1 mm |

| Cleanliness | ISO Class 2 | ISO Class 2 |

| Axis | R Axis | T Axis | Z Axis |

|---|---|---|---|

| Stroke | 400 mm (Single) / 445 mm (Double) | 340° | 300 mm |

| Speed | 200°/s (1,117 mm/s) | 400°/s | 500 mm/s |

| Utility | Power Source | Vacuum Pressure | CDA Pressure |

| AC 200/230 V ±10% | ≤ –80 kPa | NA | |

| Others | Mapping | Mount Type | Weight |

| Included (thru-beam) | Bottom Mount | Approx. 32 kg |

Controller

| Model | VRC4400 |

|---|---|

| Interface | RS232C Ethernet and parallel photo I/O |

Features

Reduces wafer handling time by using a dual arm

Enables fast and safe wafer handling with precise operation and optimized motion

Selectable base type or flange type depending on the installation environment of the equipment

Provides high reliability and maintenance convenience

Allows encoder battery replacement without opening the cover

Intuitive teaching pendant UI configuration

VSW-D4160

Cleanroom-Compatible VSW Series

Uses an absolute servo motor, offering high precision and reliability.

Applies various types of grippers, making it suitable for work transfer in different environments.

Features

Enables fast and safe wafer handling with precise operation and optimized motion.

Selectable base type or flange type depending on the installation environment of the equipment.

Provides high reliability and maintenance convenience.

Allows encoder battery replacement without opening the cover.

Intuitive teaching pendant UI configuration.

Robot

| Specification | Index WTR Single | Index WTR Double |

|---|---|---|

| Model | VSW-S3160-300-AV-M | VSW-D4160-300-AV-M |

| Handling Object | 8 inch Wafer (STD) | 12 inch Wafer (STD) |

| Grip Method | Vacuum grip (STD) | Vacuum grip (STD) |

| Min Rotate Dia. | Ø 450 mm | Ø 570 mm |

| Gripper Reach | 525 mm | 580 mm |

| Configuration of Axis | R / T / Z (3 Axis) | R1 / R2 / T / Z (4 Axis) |

| Coordinate System | Cylindrical | Cylindrical |

| Repeatability | Within ±0.1 mm | Within ±0.1 mm |

| Cleanliness | ISO Class 2 | ISO Class 2 |

| Axis | R Axis | T Axis | Z Axis |

|---|---|---|---|

| Stroke | 400 mm (Single) / 445 mm (Double) | 340° | 300 mm |

| Speed | 200°/s (1,117 mm/s) | 400°/s | 500 mm/s |

| Utility | Power Source | Vacuum Pressure | CDA Pressure |

| AC 200/230 V ±10% | ≤ –80 kPa | NA | |

| Others | Mapping | Mount Type | Weight |

| Included (thru-beam) | Bottom Mount | Approx. 32 kg |

Controller

| Model | VRC4400 |

|---|---|

| Interface | RS232C Ethernet and parallel photo I/O |

Features

Reduces wafer handling time by using a dual arm

Enables fast and safe wafer handling with precise operation and optimized motion

Selectable base type or flange type depending on the installation environment of the equipment

Provides high reliability and maintenance convenience

Allows encoder battery replacement without opening the cover

Intuitive teaching pendant UI configuration